Shop with confidence

Explore related items

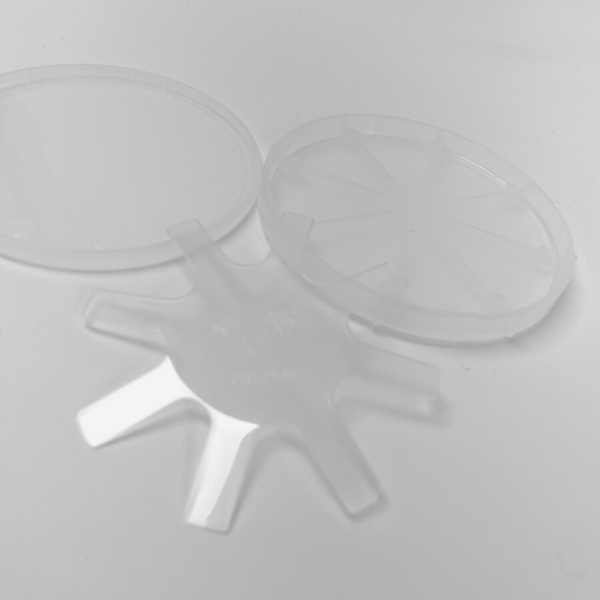

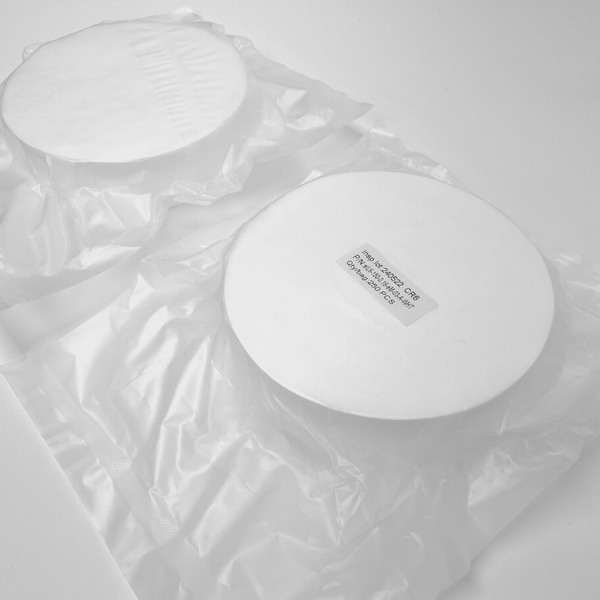

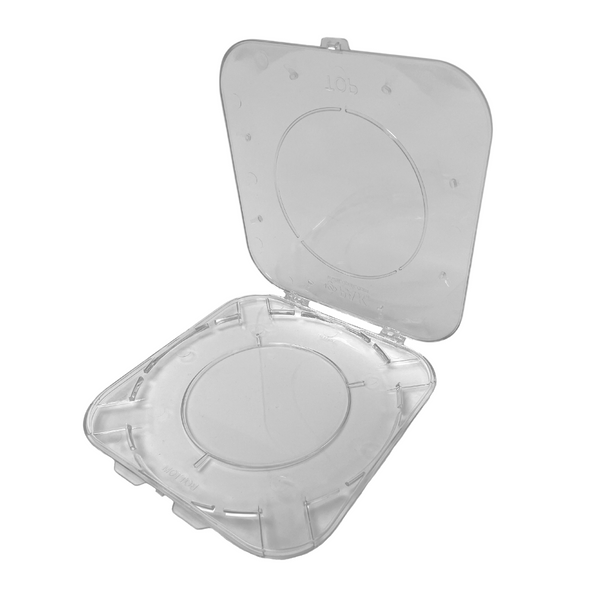

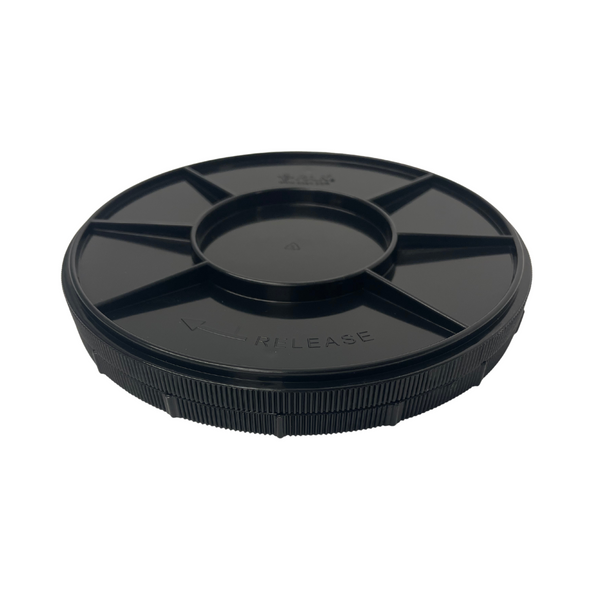

Cleanroom-Ready Design

Each wafer shipper is thoroughly cleaned with deionized water after molding and packaged in a cleanroom environment. This ensures the container is free from contaminants and compliant with cleanroom and wafer handling standards. All components are brand new and ready for immediate use in sensitive semiconductor processes.

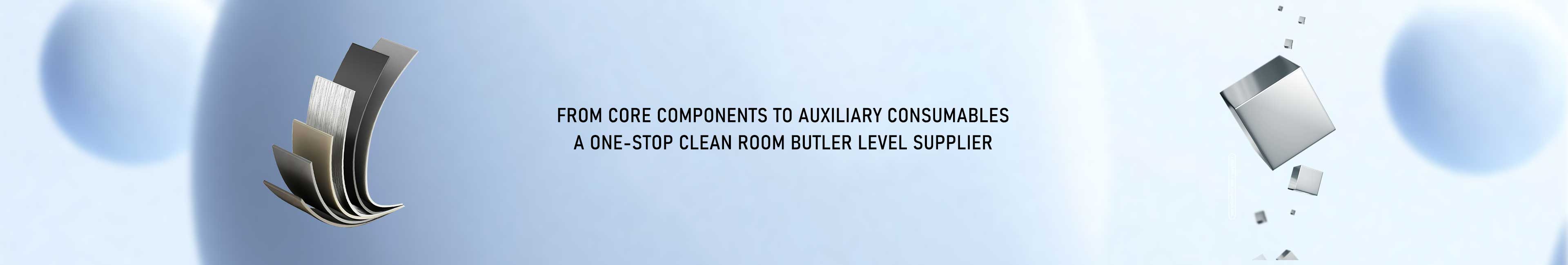

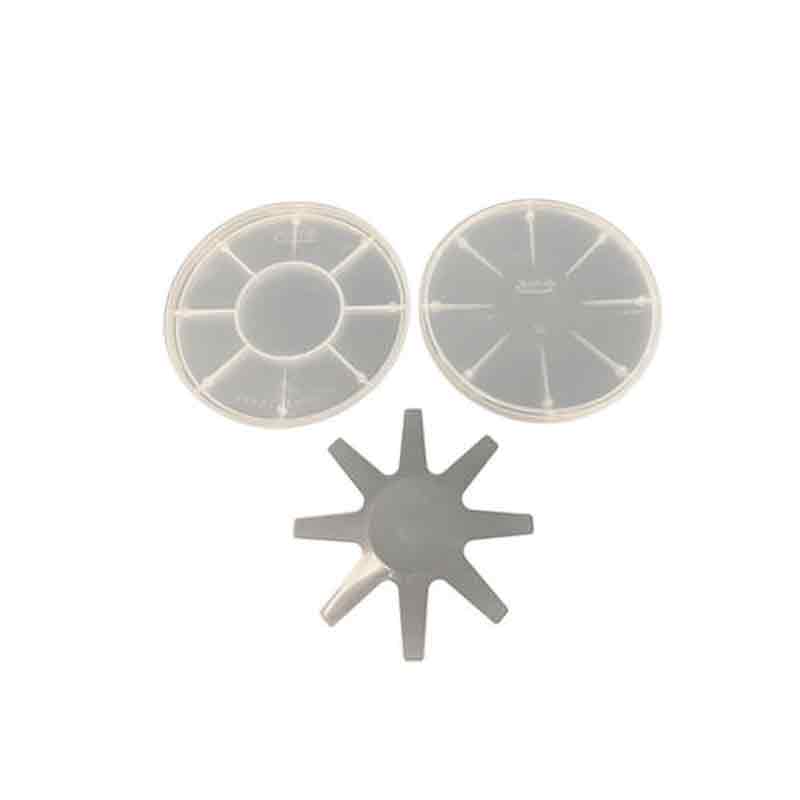

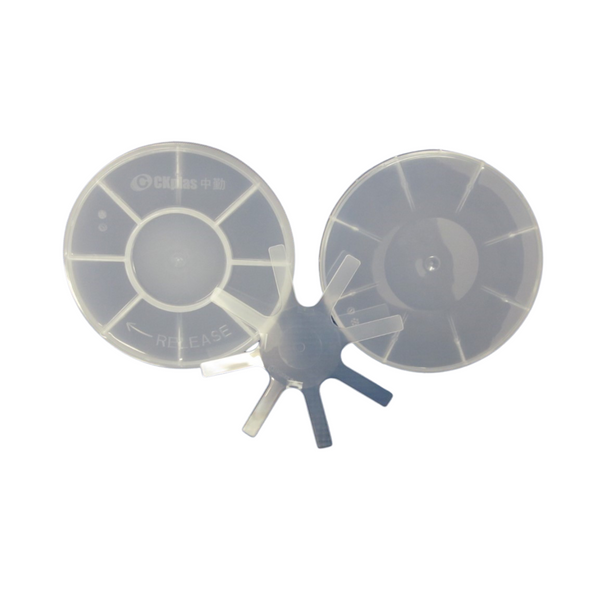

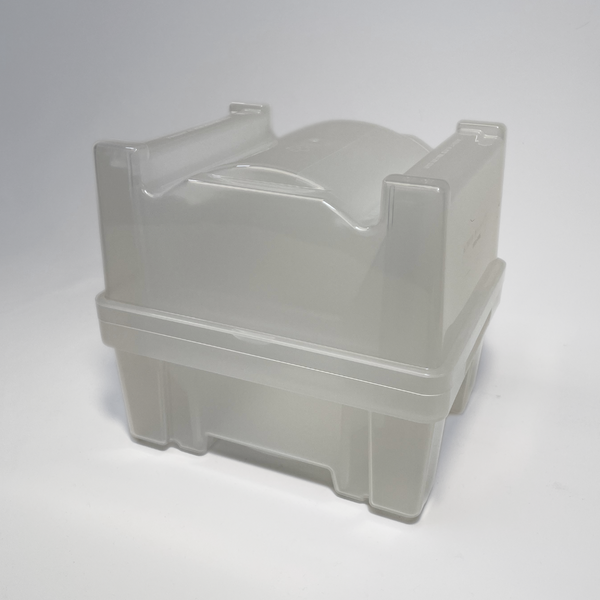

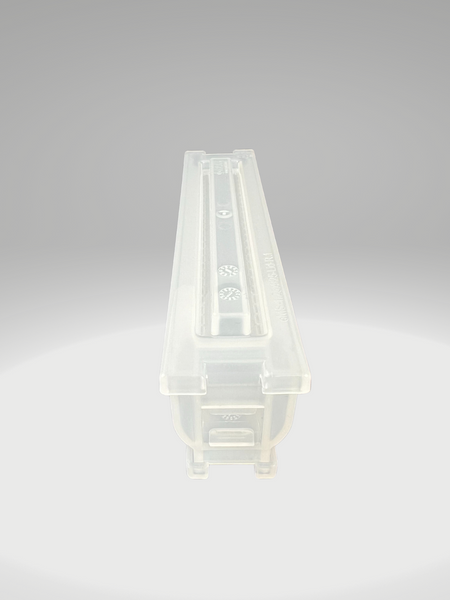

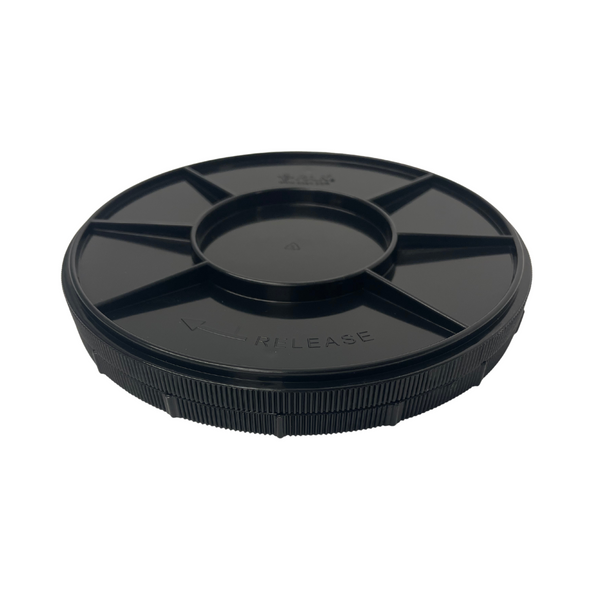

Secure Wafer Protection

The shipper adopts a two-piece structure with wafer trays integrated inside. Independent horizontal spring mechanisms securely hold the wafer in place, preventing movement, vibration, or edge damage during transportation and handling. This design effectively protects the wafer surface and edges, ensuring high yield and reliability.

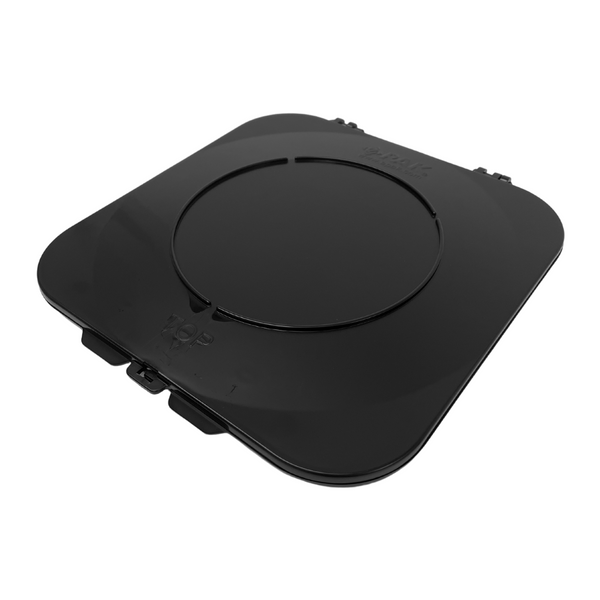

Material and Physical Properties

Material: High-purity polypropylene (PP)

Color: Black (ESD-safe)

Inner Diameter: 152 mm (suitable for 6-inch / 150 mm wafers)

Specific Gravity: 0.9 g/cm³

Melting Point: 164°C

Dielectric Property: Low dielectric constant, providing excellent insulation and ESD protection

Chemical Resistance

The polypropylene material offers strong chemical stability and is resistant to isopropanol (IPA) and acetone, allowing safe use during common cleaning and handling processes without material degradation.

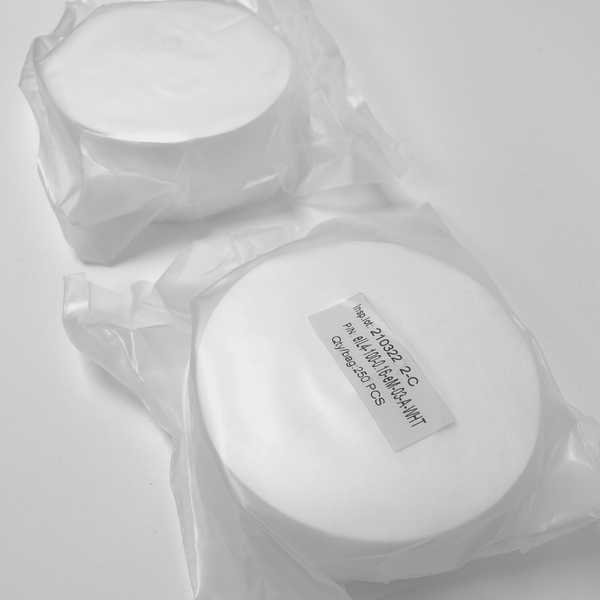

Packaging Specification

Capacity: Designed for 150 mm wafers

Packaging: 10 pieces per pack

Applications

This 6-inch ESD wafer shipper is ideal for:

Semiconductor wafer transportation

Wafer storage in cleanrooms

Fab-to-fab or internal logistics handling

R&D, testing, and production environments

With its cleanroom-compliant processing, reliable ESD protection, and robust mechanical design, the 6-inch ESD wafer shipper provides a safe and efficient solution for protecting valuable semiconductor wafers throughout their lifecycle.